|

|

|

Solving Overheating Problems

~~~

Subtopics related to overheating are as follows -

As we all know, the babies we all love so much are cooled by air.

Adequate cooling of the VW engine, and the flip-side, overheating,

are concerns.

In any system in which work is being done, the Second Law of Thermodynamics

dictates that some of the energy produced is wasted in the sense

that it cannot be utilized for work. This waste energy, in the form

of heat, must be transferred to a “heat sink.” In a water-cooled

car, the water circulating through the engine block and heads carries

the waste heat to a radiator, where the waste heat is dumped to

the atmosphere. The atmosphere is also the “heat sink” in the aircooled

VW engine, but in Volkswagens the waste heat is removed from the

engine by flowing air rather than water. Finning on the heads and

cylinders facilitates the heat removal, and a cooler is provided

in the system to remove heat from the engine oil; heat is also carried

from the oil cooler by flowing air.

We are often asked, “What is the best way to keep my Bug cool?”

And being the stock enthusiasts that we are, we respond, “You already

have (or perhaps, had) everything you need.” Volkswagen engineers

recognized from the outset the importance of keeping the engine

cool, and they came up with a very efficient design, consisting

of a blower (fan), a set of air vanes, thermostatically controlled

flaps, air dams and deflector plates. This system is designed to

efficiently direct the flow of cooling air toward the cylinders

and heads, paying particular attention to the exhaust valve areas

of the heads.

The smart VW owner will watch carefully for the tell-tale signs

of overheating. In his technical manual, Gene

Berg states that the safe upper oil temperature is on the order

of 235°F (113°C) so. If the temperature is higher than 235°F, the heat

can cause case studs to pull out, head and case sealing surfaces

to warp, cases to be internally distorted, permanent case metal

fatigue and engine bearings to wear prematurely. Sounds like a horror

story, but it is easily prevented if a few precautions are taken

and followed religiously.

~~~

Know If Your Engine Is Running Too Hot?

There are several of ways -

- The “Poor Man’s” Dipstick Test -

With the engine completely warmed up, grab the dip stick and

pull it out. If you can JUST hold it without it burning your fingers,

the engine temperature is OK. If it burns your fingers (and the

engine will usually smell hot too), then the temperature is too

high -- possibly as high as 285°F (140°C) -- VERY hot!

- Install an Oil Temperature Gauge -

An oil temperature gauge requires an oil temperature sensor/

sender. There are two types of oil temperature sensors -

- Oil Sump Plate Sensor. This sensor will screw into the oil

drain plug hole, but the sensor extends upward enough that it

impinges on the oil screen assembly. The instructions that come

with this sensor say to drill another hole in the plate, to

one side of the plug, thread it, and install the sensor there.

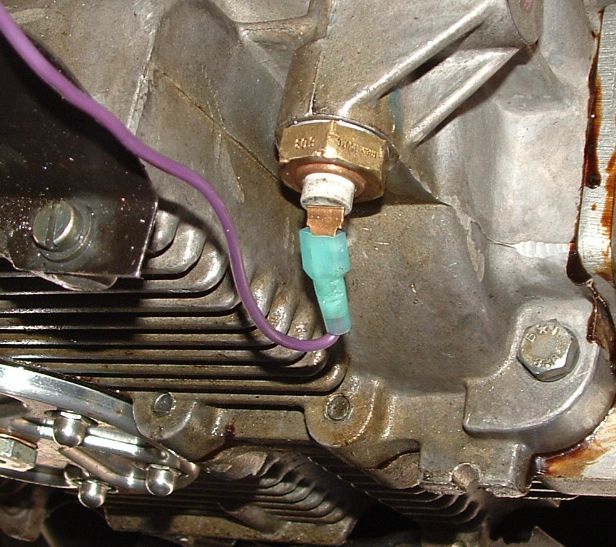

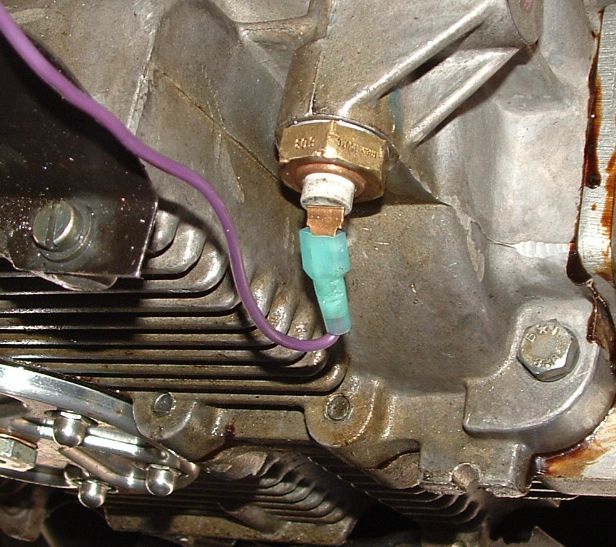

- Oil Pressure Relief Plug Sensor. If your engine is equipped

with a dual oil pressure relief system, you can install an oil temperature in the plug at the rear (pulley end) of the engine - the oil pressure relief valve (NOT in the oil pressure control valve at the front (flywheel end) of the engine). When installed as the plug in the oil pressure relief valve, the sensor will be picking up the oil directly from the sump so it will be measuring the temperature in the bulk of the oil - as it leaves the sump. Placing the temperature sensor at the flywheel end of the engine (oil pressure control valve) would mean the oil has picked up heat direct from the crankcase which might be higher than the sump temperature - less representative of the bulk of the oil. If your engine does not have a dual relief system, you will have to install the oil temperature sensor in a hole you drill and tap in the oil sump plate.

Oil Temperature

Sensor

Oil Temperature

Sensor Installed in the Oil Pressure Relief Valve

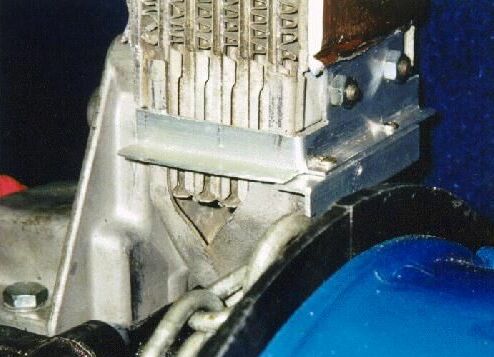

Note: This picture shows the oil temperature sensor correctly installed in the

oil pressure relief valve at the pulley end of the engine. Note the wire running forward

-- be sure to attach it securely with clips or cable ties so

that it doesn’t interfere with the workings of the heater boxes,

etc.

~~~

Wiring instructions come with the gauge (e.g., VDO). Generally

speaking, you run a wire from the sensor up to where you install

the gauge in the cabin. You will need to drill a small hole in

the floor pan behind the rear seat so you can route the wire into

the area under the rear seat, then forward from there). To wire

the gauge you simply connect the gauge to power (we used the #11

fuse) and to ground, and you’re all set. In our Superbug we found

a nice place in the dash to install the gauge, just to the left

of the steering column.

Oil Temperature

Gauge.

We found the perfect location for our gauge in the dash panel

of our Super, immediately to the left of the steering column.

Access is a bit difficult unless you remove the steering wheel.

Using a right-angle attachment on the drill, we drilled a series

of holes around the circumference of the larger hole for the

gauge, then connected them with a coping saw blade. A bit tough

on the fingers!

~~~

A word of caution from Gene Berg: “Practically all (temperature

gauges) read low in the 212°F to 260°F (100°C to 127°C) degree range by 40°F to 50°F (4°C to 10°C) degrees

...”

I found this to be true with the sensor installed in the oil pressure control valve at the front (flywheel end) of the engine. I inserted a candy thermometer with a 6-inch probe in the dipstick hole (calibrated at the boiling point of water - 212°F (100°C). Following a half hour run at full speed on the highway, ambient temperature 95°F (35°C), the gauge I installed in the dash read 182°F (83°C), while the candy thermometer in the dipstick hole read 220°F (104°C). However, with the sensor installed in the oil pressure relief valve plug at the pulley end of the engine, the temperature readings on the gauge in the dash and the candy thermometer in the dipstick hole were virtually the same.

Reading Temperature with a Candy Thermometer!

~~~

I was very disappointed - installing the oil temperature gauge was a lot of work. Much simplier is either the candy thermometer trick or Gene Berg's temperature-sensing dipstick, described below.

- Install a Temperature-Sensing Dipstick -

This sensor is sold by Gene

Berg Enterprises. It installs in the dipstick hole and connects

with a wire the oil pressure switch. When the temperature reaches

about 225°F (107°C), the spring inside of the dipstick turns to make electrical

contact, and the oil light in the instrument cluster begins to

flicker. As the temperature increases, the oil light will flicker

more rapidly until it remains on continuously -- which means your

oil temperature is dangerously high.

Temperature-Sensing

Dipstick.

This ingenious device was invented by Gene Berg and is

marketed by Gene

Berg Enterprises. The dipstick is

calibrated to signal a warning at 225F (107C).

Connection to the

Oil Pressure Sensor.

The wire from the dipstick connects to the wire running up

to the oil pressure warning light in the instrument cluster.

It’s easiest to make this connection right at the oil pressure

switch, using a three way connector as shown here.

~~~

With the temperature-sensing dipstick, you don’t get any indication

that the temperature is rising until the oil light flickers, telling

you the oil is becoming too hot; but at least you can do something

before any damage occurs. The dipstick is very easy to install in

the car, since it uses the existing dash oil pressure light as an

indicator.

~~~

How Do You Keep the Operating Temperature

Within Safe Limits?

Below are some things that you can do (short of pulling the heads

and fussing with the compression ratio. Rob Boardman: “Dropping

the compression ratio is counterproductive; more compression means

a more efficient engine.")

- Put a larger main jet in the carburetor. A larger main jet makes

for more evaporative cooling of the inlet, so the engine runs

cooler. This works for an engine which is running too lean (running

lean makes any engine run hotter), but it doesn't do as much good

for a car which has the right mixture already.

- Make sure that the air correction jet is the right size. A feature

of all open-throat type carburetors is that they tend to run over-rich

as the airflow increases through them. The air correction jet

is used to adjust this mixture. This jet adds air to the fuel

delivery nozzle, so larger numbers mean leaner at higher speeds.

With the stock Solex carburetors (or their modern Brosol and Bocar

replacements), the air correction jet is usually in the 110-130

size range. If it's up around 140-170 it's running the car lean

at higher speeds (it does very little at low speeds).

- Make sure the power jet (in the right side of the carburetor

near the idle jet) is the right size. From the 30PICT/2 carburetor

onwards (and the modern replacement Brosol and Bocar models),

a power jet was added which re-enrichens the mixture at full throttle

and high rpm, because the air correction jet works too well at

the carburetor’s maximum airflow. Without the power jet (or with

one which is too small), the engine will run lean at very high

rpm and high throttle, and as noted before, running lean makes

the engine run hot. The most common power jet size is 65. The

power jet feeds fuel, so larger means richer.

Note: The jets in Dave's Pierburg 34 PICT/3 carburetor are X130 main, 80Z air correction, and 55 idle.

- Make sure the cooling vanes and thermostat are working properly

and that the connecting rod is shaped properly to prevent binding

between the cylinder head fins. When you have the engine out,

make sure the flaps are opening easy and all the way -- you may

have to unscrew the push rod from the thermostat, but you should

then be able to push it up and down easy enough and check the

flaps.

VERY IMPORTANT NOTE! Make ABSOLUTELY SURE the cooling vanes and thermostat are working properly! Dave learned this lesson in a very sad way. Shortly after building up a new long block and installing it in his Bug, Dave took the car for a long run up a very steep hill (Cabbage Hill, Oregon) on a very hot day. The result was a fried engine, caused by a malfunctioning thermostat. (Actually the thermostat worked just fine; the stud that holds the thermostat bracket to the engine block came loose, and the thermostat pushed the bracket down instead of pushing the connecting rod up, so the cooling vanes were locked closed.) A very costly oversight!

Cooling Vanes(3)

This picture is looking up into the fan shroud on either side,

where you can see the moveable cooling flaps. The connecting rod

is also visible; this rod is moved upward by the expanding thermostat

to gradually open the cooling flaps. Fully open, the flaps properly

direct the flow of cooling air over the engine cylinders and heads.

Please don’t remove the cooling vanes and thermostat -- they provide

a very important function.

~~~

Old-Style Thermostat(3)

This is the stock “bellows” style thermostat, shown installed.

These are not longer made and are becoming increasingly rare.

~~~

The original style thermostat is no longer made and is becoming

more and more difficult to find. A very good option is to use the

new-style thermostat pictured below. This thermostat is the original

replacement style for Mexican fuel-injected Beetles made from 1975

to 1979 and is a suitable replacement for the old bellows-style

thermostat. The thermostat provides enough upward movement of the

connecting rod to fully open the flaps on both Type 1 and Type 4

applications.

Note: The fan associated with the "doghouse" oil cooler

provides plenty enough air to cool up to about 80hp (a warmed up

Type 4 engine in a Bug for example), but to get best effects you

have to ensure every bit of cooling air goes where it's most needed.

That means you must have the cooling flaps above the cylinders --

with these fully open more air is directed to the hotter heads and

less to the cooler cylinders. The cooling flaps also work with the

thermostat to provide a fast, even warm-up on those cold mornings.

The importance of cooling flaps used to be misunderstood and many

have been removed by engine builders as “not needed”, but they are

essential in getting more air where it’s needed most – the cylinder

heads.

New-Style Thermostat

The “Mexican-style” thermostat, used in ’74 - ’79 Mexican Bugs.

New-Style Thermostat

Installed

Fortunately the “Mexican-style” thermostat perfectly

replaces the older bellows style and is very easy to install.

~~~

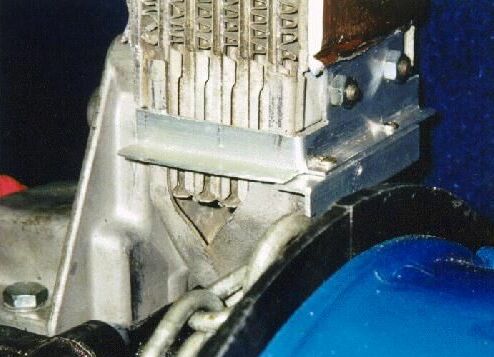

- Test the oil cooler and replace it if it is plugged. Make sure

the "Hoover bit" around the bottom of the oil cooler

is there. This is a roughly L-shaped bracket which seals off the

underside of the oil cooler on doghouse engines, preventing spillage

of cooling air back into the engine compartment. A lot of folks

don't realize just how important this piece is and remove it.

The “Hoover Bit”

This piece, which wraps around the bottom of the

oil cooler and prevents spillage of heated air back into

the fan, is often removed and discarded. The piece

must be left in place to assure that hot air is not

sucked back into the fan.

~~~

Note: Be careful not to over-torque the nuts on the oil

cooler studs – you might squash the small rubber seals too much

and reduce the oil flow through them.

- Make sure the tin is properly fitted around the oil cooler to

assure heated air from the oil cooler is being dumped to the outside,

not back into the area in front (front means front of the car)

of the fan where it can be sucked back into the system.

Note: The doghouse tin fits inside the exhauster tin (i.e., the downspout that dumps hot air from the oil cooler out under the car). The fit is seldom perfect - we fixed this by wrapping some stout, heat-resistant tape (e.g., "Gorilla" tape) around the joint to keep hot air from being sucked back into the fan.

- Make sure the drive belt is properly adjusted, but not TOO tight

-- you don't want to ruin the alternator bearing. A half-inch

deflection in the center of the belt, when pressed with your thumb,

is about right. You'd normally start off a new belt with 3-4 shims

and work up to 5-6 shims as the belt wears. Replace the belt as

soon as it shows signs of wear – cracks or fraying. Always carry

a spare fan belt – without it your engine will fry in minutes.

- Use the stock black valve covers on the heads -- black covers

radiate heat better. We've heard it said that using the stock

black valve covers will reduce the oil temperature by as much

as 30F (17C). Fancy valve covers might look good, but the stock

ones are better for correct engine temperatures. (Years ago VW

used to supply an arctic kit for engines to be used under very

cold conditions. This kit included chrome valve covers to keep

heat IN the engine.)

Stock Black Valve

Cover

We removed our “cool” shiny aluminum valve

covers and went back to the stock black ones.

We’ve noticed asignificant decrease in the

engine operating temperature as a result.

~~~

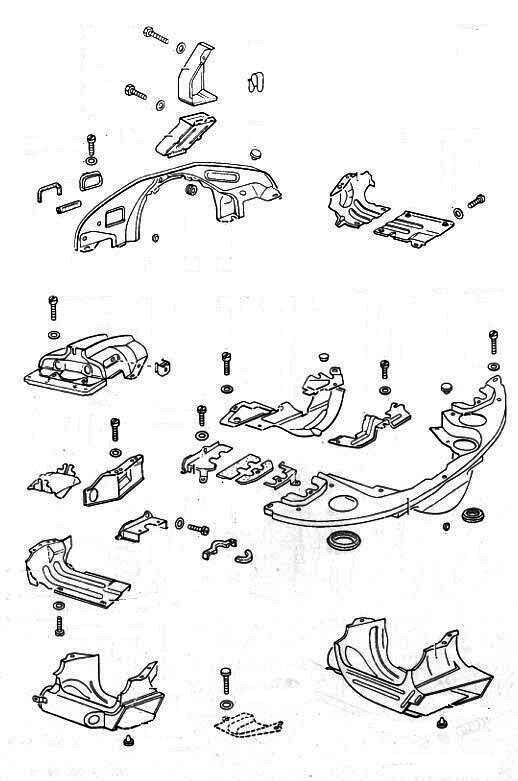

- Make sure all of the engine tin is fitted properly and all of

the seals are in place to assure that only fresh air is being

sucked into the engine compartment and thus into the fan - not

hot air from under the engine. This includes the seal around the

engine, the engine lid seal, the holes in the tin through which the spark plug wires pass, and any other holes in the tinware. Doing

this will reduce smell in the cabin when the heaters are on, too.

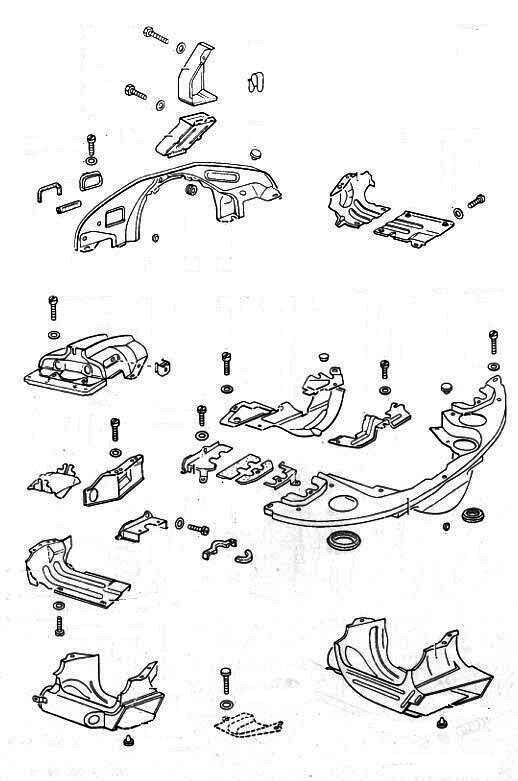

Engine Tin

This great exploded view of the engine tin, courtesy of

the Old Beetle Home, shows all of the tinware

pieces,each specifically design to maximize the flow

of cooling air. Please make sure they are intact!

New Engine Seal

An excellent replacement for the stock rubber seal,

especially if you’re having trouble with the seal falling

down onto the muffler around the rear.

Sold by Aircooled.Net.

~~~

Note: Dave installed a fiberglass rear apron on his '73

Super Beetle. This apron does not have the slot for the stock rubber

engine compartment seal, so the stock seal would not stay in place

but kept falling down onto the muffler (or header as the case may

be). Dave discussed this situation with John Connolly of Aircooled.Net

and decided to go with an alternate seal that John recommended,

shown in the picture above. This seal is used in the 1972 and newer

Type 2's and the Type 4 VW. The seal is just pressed down into the

space between the engine tin and the body of the car, making it

much easier to install and much more effective in sealing this gap.

- Make sure the rubber air dams around the spark plug leads are

in place and properly fitted. We’ve heard it reported that there

is a 25F (14C) rise in head temperature with these left off. They

harden with age and can then slide a little way up the plug lead,

resulting in a lot of leaking air. If they are not soft and flexible,

replace them.

- Make sure the deflector plates under the cylinders are in place.

There is a small flat plate on each side, between and under the

cylinders, and an even smaller one under the center of each cylinder

head (on the right side the under-head deflector has a slot in

it for the thermostat pushrod). These are vital for good cooling.

They force the cooling air through the underside finning -- without

them the cooling air spills straight down and does not provide

much cooling for the underside of the heads or cylinders. Some

folks leave them off, not realizing how important they are.

- While you are under the engine, make sure the underside plenum

pieces of tinware are in place (a large curved piece of tinware

under the left side and two pieces on the right so the thermostat

can be easily changed). These turn the used cooling air backwards

to the rear of the car. If they are left off, the underside engine

finning is exposed to the turbulent high pressure air under the

car and poor cooling will result. On the stock engine the cabin

heat exchangers are used to dam off the outer sides of this plenum,

and if you have replaced the heat exchangers with J tubes you

still need to seal the outer edges of the plenum with some cut-to-measure

pieces of flat metal.

- "Cool tins" are used on Type 3 (pancake) engines to improve

underside cooling and can be fitted to the Beetle engine too.

They replace the cylinder deflector plates (the head deflectors

stay in place) and cup the underside of the cylinders so all the

cooling air is forced through the underside and out through the

exit holes in the tinware. They also have "ears" which cup the

outer corners of the head near the exhaust valves so that those

valves get a better flow of air through the fins there. They work

by actually reducing the cylinder air flow a little (but using

it better), and this results in a higher airflow through the heads,

so cooling is supposedly improved there too.

Note from a source we trust - Cool tins have been tested and it has been proven that they do not work well with the Type 1 fan and cooling components. It was more of a "hey we have a warehouse full of these, lets market them" gimmick than a real solution.

“Cool Tin.”

You shouldn’t need the “cool tin” if all of the other

parts of your cooling system are in place and

functioning. But it is available at minimal cost

(e.g., from Aircooled.Net)and

is easy to install

(with the engine removed from the car).

~~~

You have to remove the engine to install the cool tin, and to fit

them to the Type 1 Beetle tinware they might need to do a little

cutting and bending. They are not really needed for a stock Beetle

engine, but if you have a higher performance engine or are experiencing

cooling problems, they might help. (We have not personally used

"cool tin" and cannot vouch for its effectiveness. It helps, though,

according to the experts.)

Overheating as Related to the 009 Distributor

Someone wrote -

I read on your site about VW's running hot.. What I miss in this

discussion is the distributor, which is often an 009 centrifugal-advance

distributor. Since the 009 will be over-advanced in certain conditions,

will this not be a key problem with overheating?

Rob responded -

The 009 distributor results in the engine running UNDER advanced

rather than over advanced, and in fact under-advance running will

cause an increase in engine temperature. The 009 distributor doesn't

begin to advance until about 1200 rpm while the vacuum distributors

will add about 8 degrees advance just as soon as you open the

throttle off idle - this helps the engine spin up smoothly. The

009 distributor must be limited to about 30 degrees maximum advance

because at that setting the engine will not detonate/ping if you

floor the throttle (think of it as a safety limit). But the vacuum

units can provide up to about 40-42 degrees advance under the

right conditions (for more engine efficiency and better economy),

and back-off that extra advance (back to around 30 degrees) if

you floor the throttle until the engine speed catches up to the

new throttle position - gradually re-introducing the final amount

of advance.

Summary of the Ways to Increase Cooling

(by Rob Boardman)

- Correct casting imperfections in the heads. If you look through

the finning on VW heads, you'll often find "dags" of metal between

the aluminum head finning which partially blocking the airways.

(This is not a problem with the cylinders - just occasionally

with the heads.) Removing these "dags" with a rat-tail file, a

chisel, a Dremel, etc. will smooth the air path through the head

fins, thus improving airflow and cooling of the heads.

- Use the standard VW pulley -- not a "power pulley." These spin

the fan slower and reduce cooling. A “power pulley really isn’t

worth it -- you gain about 1 hp at the wheels for the loss of

maybe 20% of your cooling air -- a BAD trade-off).

- Run higher octane gasoline. This will help if you have been

running a too-low octane fuel, but won’t help if you already use

the correct octane. But don’t think “higher is better” either.

A too-high octane number will not harm the engine in any way,

but won’t help it run any better either. The stock 1200 and 1300

needs only 87 RON (84 AKI in the USA) and the stock 1500/1600

needs 91 RON (87 AKI in the USA). If your compression ratio is

higher than stock, then you’ll need fuel with a higher octane

number.

- Avoid oxygenates in the fuel. The most common oxygenates added

to gasoline are methyl-tertiary butyl ether (MTBE) (used extensively

the USA) and ethanol (when added to gasoline the mixture is sometimes

called “gasohol”). Because old VWs have no engine computer to

adjust the mixture on the run, oxygenates will cause the engine

to run leaner than it should, and lean means hot. If you cannot

avoid oxygenated fuel, increase the size of the main jet to return

the mixture to its proper balance. For example, fuel with 11%

MTBE (used in many parts of the USA) runs the engine 2% lean and

a main jet one size larger will fix this problem. Ten percent

ethanol in the fuel (called E10 in many countries) needs a main

jet two sizes larger to bring the mixture back into balance.

- Make sure the underside tinware is in place - both the flat

plate deflectors under the cylinders and the heads MUST be in

place or the airflow just spills straight down and the underside

cylinder/head finning doesn't see enough cooling air. Also make

sure the underside plenum tinware is in place - this turns the

used cooling air backwards out under the rear of the car. If it's

missing the cooling air meets turbulent high pressure air under

the car and this can reduce the engine cooling.

- Make sure all tinware holes between the upper and lower engine

areas are sealed, so there is no mixing of hot used cooling air

from underneath with the fresh cooling air above the engine. There

is also a very important piece of tinware under the oil cooler

- called the "Hoover bit" by a lot of VW enthusiasts - after Bob

Hoover in California (a VW Guru). It's roughly L shaped and it

is attached to the base of the oil cooler with one bolt and seals

the oil cooler so you don't get any spill of cooling air out the

bottom - it must then all pass through the oil cooler. Also check

the rubber air seals on the spark plug leads - these go brittle

with age and might get pushed up the leads and fail to seal off

the holes in the tinware where the plugs sit. Leaving these holes

exposed can increase head temperatures by up to about 25F.

- If cooling is still a problem with just the (well fitted) stock

cooling system, then fitting cool-tins might help. These were

originally designed for the type3 (pancake) engine with it's more

convoluted cooling path, but can be used on the upright cooling

system on the bug too. They replace the under-cylinder flat plate

deflector (the smaller under-head deflectors stay in place), and

they control the airflow around the cylinders much more closely.

They also have "ears" which cup the undersides of the exhaust

valves for better cooling flow around these hot-spots. To fit

to a bug there is usually a little cutting and bending to do,

but it's not a hard job. The underside plenum pieces (which turn

the used cooling air backwards) must still be used. These cool-tins

actually reduce airflow around the cylinders a little (but use

it more efficiently) and the resulting increase in pressure in

the shroud above (from the reduced airflow) provides more airflow

to the hotter running heads, for better cooling all round.

Note from a source we trust - Cool tins have been tested and it has been proven that they do not work well with the Type 1 fan and cooling components. It was more of a "hey we have a warehouse full of these, lets market them" gimmick than a real solution.

- If you are running a car with a solid engine lid (up to and

including the '69 lids), and you have a 1600cc (or larger) engine

with the doghouse fan shroud and oil cooler, then your engine

WILL run short of cooling air at higher speeds. VW started adding

slots to the engine lid from 1970 onwards, first two sets of slots

in '70 and '71, then four sets from '72 onwards, because the doghouse

fan shroud (from '71 onwards) has a 10% higher airflow than the

non-doghouse fan, and the under-window slots were not quite big

enough. As an example, my '68 with 1600cc doghouse engine (bigger

fan than the '68 1500 engine) runs too hot in summer with the

'68 solid engine lid, but much cooler with the 2-slot engine lid

borrowed from my 1970 bug (whilst it's being slowly rebuilt after

loosing a fight with a nasty Ford).

- Some think that installing an oil sump will bring about greater

cooling of the oil. All of the advertisements say that adding

a sump increases cooling; however, Gene Berg says it just gives

you more hot oil and is only advantageous in racing and hard cornering

applications (to prevent oil surge -- not to increase cooling).

The surface area isn't much more for additional cooling, and you

also lose a couple of inches ground clearance. Oil sumps are good

for racing, but not for cooling.

- An oil temperature gauge is always a good idea, but don't get

hung up on the actual number because it will vary with the engine,

the quality of the gauge and so on - just using it for a while

will give you an idea of what is normal for your engine in different

driving styles, and then if you see if above the "normal" you

will recognise it as such.

- One very simple idea is to install a Gene Berg dipstick. This

replaces the normal dipstick and one wire connects to the oil

pressure sender just behind the engine pulley on the left side

of the case. This sensor will then start the oil pressure light

in the dash flickering at about 215F (I think - I forget the exact

number) and turn it on steady at about 225F (or something like

that). The oil light will still come on steady if the oil pressure

drops too.

So you don't get much indication of the temperature starting

to rise, but you get a good warning once it's become too hot,

and you can back off the power, change down a gear on a long hill

climb or whatever, before the engine gets REALLY hot.

- Driving style can certainly affect the engine temperature. Constant

hard acceleration and braking will heat the engine. If you have

to brake hard then you’ve just used more engine power than you

needed. Always shift down a gear before the engine starts to lug

on long hills or when towing a heavy load -- this unloads the

engine and increases the fan speed for better cooling.

- Regarding cooling the engine while driving – when hill climbing, if the speed drops below 50mph, shift down the third gear. This speeds up the fan for better cooling. If you need to, you can drive

a Bug in 3rd gear up to 60mph - it sounds very noisy but the engine

is running at a very safe 4500 rpm or so at that speed in 3rd

gear. The extra fan speed will certainly lower both oil and cylinder

head temperatures.

We’ve occasionally

heard of people driving at low speeds in 4th gear -- low rpm --

to reduce the temperature of an overheated engine. In fact it

works just the other way around. Since the oil cooler is in the

cooling fan's air stream, the best way to cool a hot engine is

to cruise in 3rd gear rather than labour the engine in 4th. This

way you are keeping the cooling fan's speed up without asking

for any extra power from the engine.

- It has been suggested that the thermostat be removed during the hot summer months, then replaced in late Autumn. Rob suggests that it is better to leave the thermostat in place, particularly if you have an oil temperature gauge in the dash and can monitor the oil temperature. Then as you do a run you can watch the temperature. If it does start to get up towards 225F, back off to 50 mph or so and see if it settles back down after a few miles (it won't be instant). If you know that the thermostat is expanded when the engine is hot, removing it will not provide any extra cooling.

There you have it. Use all the stock parts of the cooling system,

properly fitted and without any exposed holes in the tinware, use

the right fuel, set the carburettor mixture right, drive sensibly,

and your engine will run in its preferred heat range in summer or

winter.

Credits and references -

*

* * * *

|

|