|

||

|

|

Compufire Electronic IgnitionQuicker Starting, Better Performance and Better Gas Mileage." for their contributions to this procedure. There are two moderm methods to improving your igntion (spark) performance in the VW engine. Note: This procedure describes the installation of a CompuFire Points Replacement system in a SVDA distributor. See Capacitive Discharge Ignition (CDI) for discussion of that system and an installation procedure, including wiring. The wiring interface between the CDI and CompuFire systems is discussed in the following. CDI systems can be triggered by the original points, or (better) a Points Replacement Module. Make sure which version CDI you get matches your chosen method of triggering it.

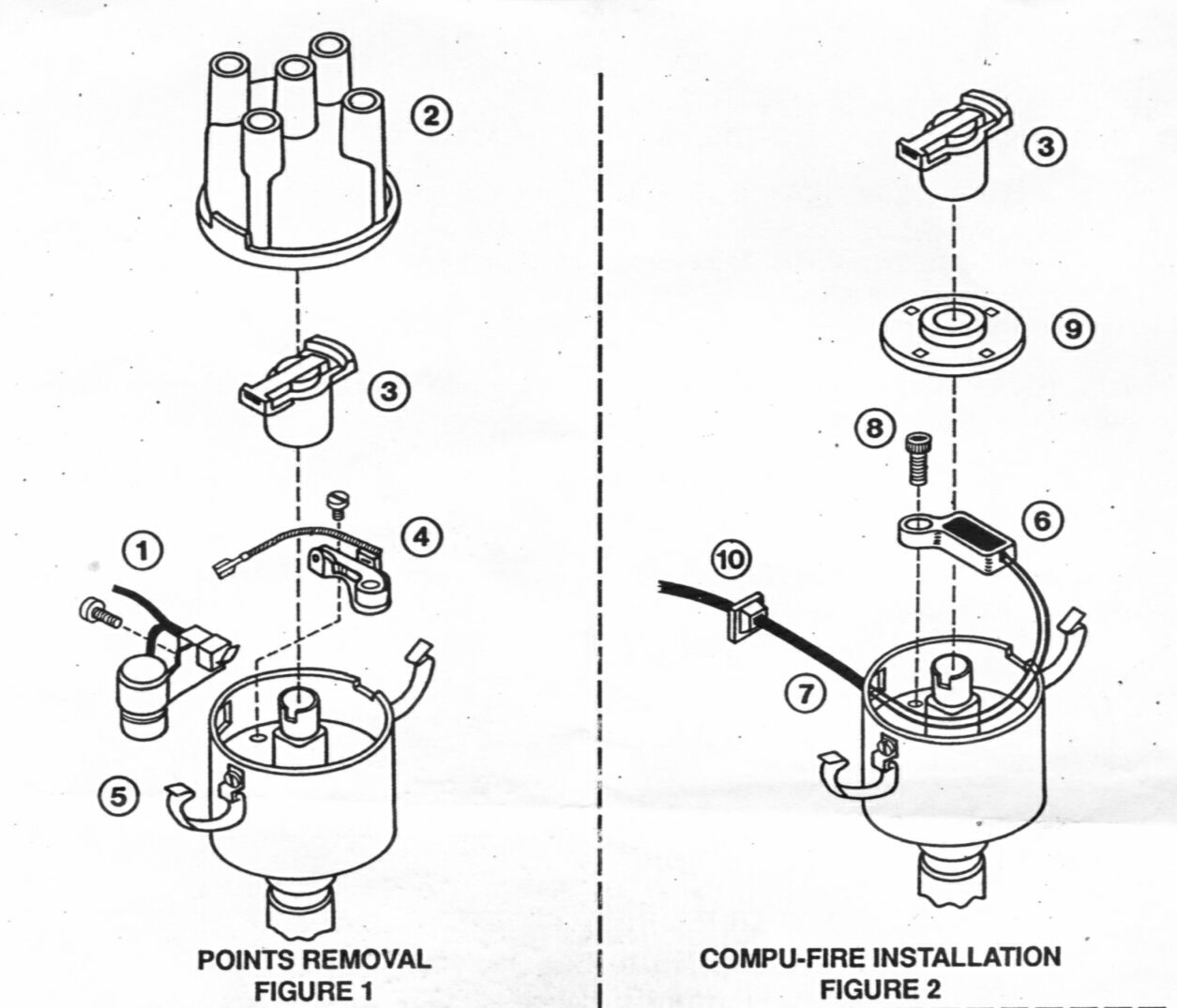

CompuFire InstallationProcedure (refer to the figure above) - Note: For high performance applications you MUST make sure your ignition coil has an internal ballast. If not, the electronic ignition in the distributor will BURN UP and leave you walking. To determine whether your coil is adequate, measure the resistance between terminal #1 and terminal #15 on the coil. The resistance should be on the order of three ohms (when fitting a CDI unit too, a 3-4 ohm coil will work OK, but a low-ohm coil will produce a hotter spark). 3 ohm coils are available that claim to provide triple the output energy of conventional high performance coils - they have more windings in the secondary (high voltage) circuit to boost the output voltage. Caution: Before installation of anything to the electrical system, it is recommended that you first disconnect the negative battery terminal to avoid electrical shorts that may damage electrical components on the vehicle. SAFETY WARNING: Put the transmission in neutral, set the emergency brake, and block the wheels.

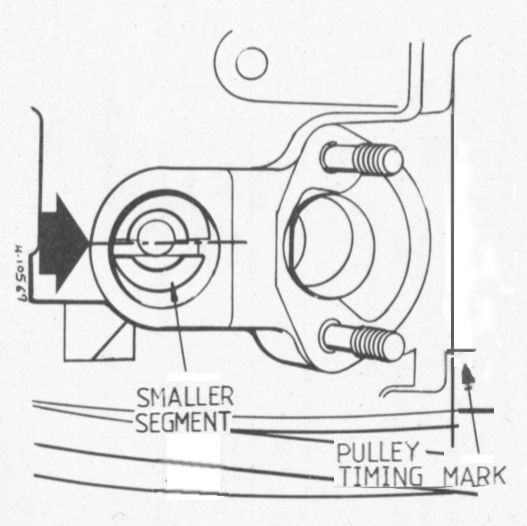

Note the side of the coil that this wire came off of. This side of the coil is the "negative" and should be marked "-" or "1". The other side is the "positive" "+" or "15". Note: If you have a Capacitive Discharge Ignition (CDI) system installed, the black wire from the CompuFire module will be connected to this green wire to the CDI unit. Note: It is a good idea to leave the plug wires installed on the cap, to keep them in order. Note: Make sure you do not lose this screw down inside the distributor! If the screw gets lost in the distributor, it may jam the advance mechanism. Using a screwdriver with a magnetic tip to remove this screw would be ideal. If you do not have a magnetic screwdriver, you can place a magnet on the shank of the screwdriver, such as a refrigerator magnet. The steel bottle/can opener refrigerator magnets usually have a decent magnet on them. Tip: you can magnetise a normal screw driver by wiping one side of a strong magnet repeatedly down the shaft. Note: Depending on the location of the condenser, you may need to loosen the distributor clamp and rotate or remove the distributor to gain access to the small condenser screw. We found it easiest to just remove the distributor. That way you have easy access to the condenser screw and you can install the CompuFire system conveniently on your workbrench. If you do rotate or remove the distributor, put a thin line of white paint on the distributor body running down on the distributor clamp and the engine case. That way you will be able to reinstall the distributor just as it was to maintain the timing. Important note: If you've been timing your SVDA or 009 distributor statically, you'll need to invest in a strobe timing light -- once you have the CompuFire system installed you will no longer be able to time the distributor statically, since there are no points. Note: On our SVDA distributor we found a black wire running from the points screw in the braker plate (underside of the points) to the body of the distributor (inside). If you have such a wire, make sure it reattaches under the points replacement module (6) just as it did before. Note: There is a slight amount of adjustment in the location of the CompuFire points replacement module (6). Make sure it does not interfere with the high point on the cam lobes. Make sure the screw is tight and does not interfere with the operation of the vacuum advance plate (it will if it's too long). Note: Make sure you have the right amount of slack in the wires inside the distributor. The wires must not interfere with the operation of the magnetic trigger wheel (9) or vacuum advance mechanism. Note: The square plastic grommet has the flange removed on one side. This side of the grommet must be located on the top side, in the direction of the distributor cap, to avoid interference with the distributor cap when it is installed. If your distributor hole is round, you will have to "round" the square grommet with a razor knife or grinding wheel. Note: It is this ring that properly sets the air gap (about 0.060") between the CompuFire module and the magnetic trigger wheel. The gap must not be outside the range of 0.030 and 0.100. Note: If the trigger wheel is not pressed firmly onto the spacer ring, the gap between it and the CompuFire module may be too wide, and the system will not operate properly. Note: Depending on which ignition rotor you have, you might have to remove some material from the bottom of the rotor so it will seat properly onto the distributor shaft. If not, it will spin freely on the shaft. If you have to remove some material from the ignition rotor, we found the easiest way to get a good flat surface was to carefully use of a bench grinder, taking off just a bit at a time. You can also use a flat file or a Dremel tool. Usually, if an ignition rotor needs to be modified in this way it require the removal of around 1/16-1/8" of material from the bottom of the rotor. Note: If you are unsure about cylinder #1 being at TDC, see our Finding TDC Procedure.

Slot in the Distributor DriveshaftWiring Instructions - Note: If you have a Capacitive Discharge Ignition (CDI) system in your car, see the second set of wiring instructions below. The Points Replacement Module with standard ignition system (no CDI) -

Wiring both the Points Replacement Module and CDI -

We used a large wire nut to connect these six wires. There is probably a more appropriate automotive connection device on the market, which we will look for. Note: If you have a CDI system installed, it is easiest to power the strobe light from the black wire that attaches to the automatic choke, as terminal #15 no longer receives power directly from the ignition switch. Note: The CompuFire ignition system is compatible with conventional electronic tachometers. Except for CDI-equipped systems, the tachometer lead remains connected to the minus (-) primary ignition coil terminal (#1). For CDI the green wire from the from the distributor goes to the CDI unit rather than to the #1 terminal on the coil. You will need to splice a wire into this green wire to create a test lead. Troubleshooting -

Note: With the CDI system, a convenient place to measure the incoming voltage is at the automatic choke terminal, connected to the black wire coming from the ignition switch.

|

||

|

|