|

||

|

|

Air CleanerTopics covered in this article include -

IntroductionA component on the VW engine that is often taken for granted is the air cleaner. Sitting as it does on top of the carburetor, the big clunky stock air cleaner always seems to be in the way on tune-up day, and the average VeeDubber is tempted to change it out for one of those shiny chrome aftermarket models. Through the 1972 model year the air cleaner was a large, round, dome-topped metal black thing with metal clips on it, possibly with several thin and fat hoses going to it. These round air cleaners, of which there are several different designs, have oil in them to clean the air before it goes into the carburetor and on into the engine. The oil is changed by removing the clips and the top of the air cleaner. In 1973 and later models, the air cleaner is a large black boxy shape with a paper aircleaner inside. It serves the same purpose as the oil in earlier models -- to remove dust particles from the air before it is drawn into the carburetor for mixture with the fuel. The cleaning medium, whether it be oil or a paper filter, should be changed every 18,000 miles.

Earlier Model Oil Bath Air Cleaner

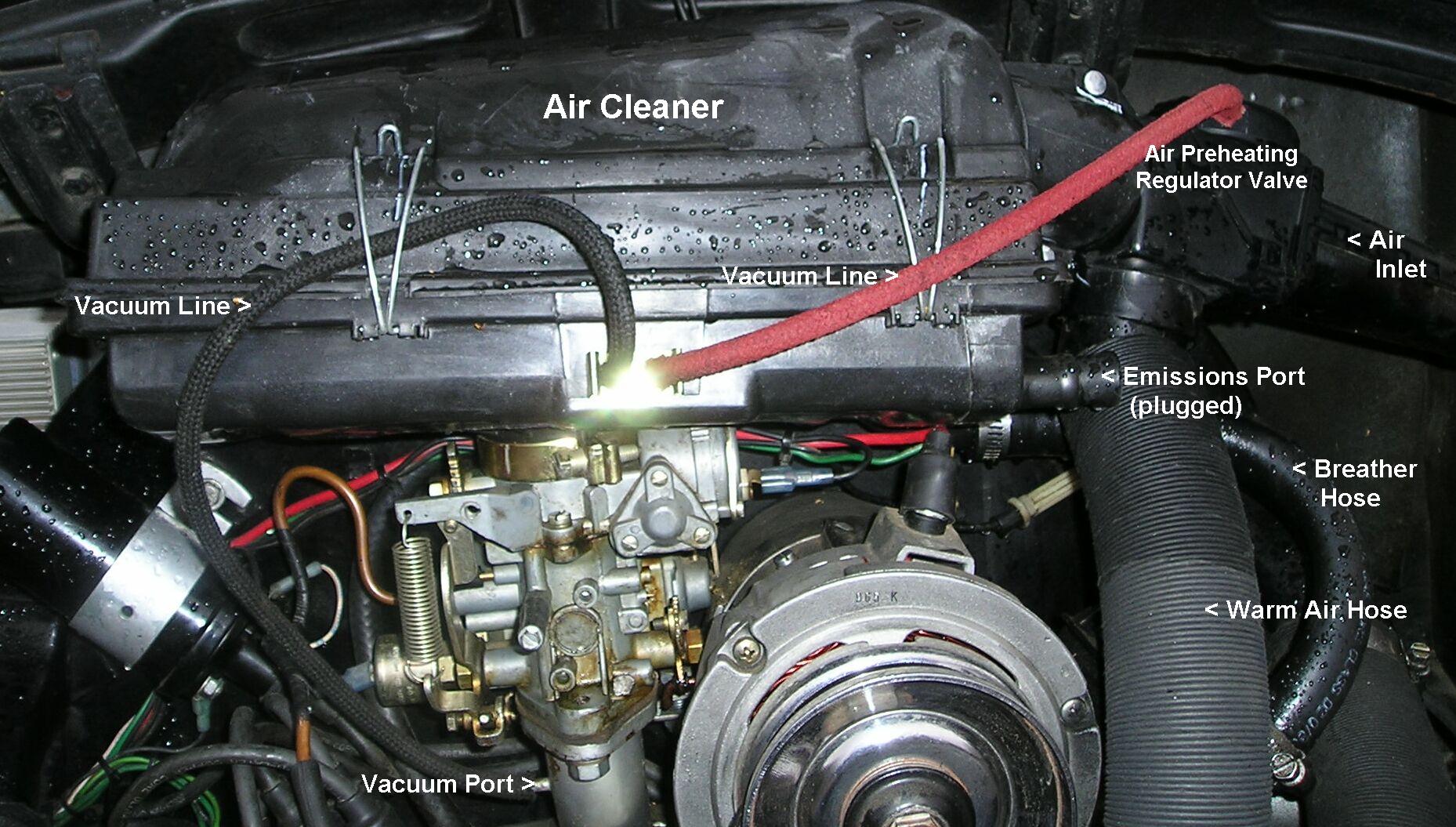

Later Model Paper-Element Air CleanerAncillary Air Cleaner SystemsCleaning the air for mixture with the fuel is the primary purpose of the air cleaner, but over the years a number of other important functions have come to be associated with it. In addition to the main air inlet port(s), there are other hoses attached to the air cleaner -- simple arrangements (or none) in early models, more complicated systems of hoses later on. These hoses are associated with the following ancillary air cleaner systems. ~~~ Crankcase VentilationIn response to clean air requirements, VW put a rubber hose (about 1/2" ID) from the oil filler pipe to the air cleaner to take the oil fumes from the crankcase to the carburetor for burning. The VW engine pulls fresh air into the crankcase from a spiral groove in the crankcase forward of (front is front) the engine crankcase pulley, thus providing positive crankcase ventilation. This air, plus the "blow by" from the cylinders, is pulled into the air cleaner (and on to the carburetor to be re-burned) by way of the breather hose from the top of the oil filler tower. When the engine draws air through the air cleaner it creates a slight vacuum inside the air cleaner. This negative pressure in the air cleaner, plus the positive pressure from the spiral groove pulling air into the crankcase, results in any oil fumes being drawn up into the air cleaner, through the carburettor, and burnt in the engine. With little or no pressure drop at the top of the breather (e.g., because of substitution of the stock air cleaner with an aftermarket one), any extra pressure in the crankcase causes the oil mist to push out past the spiral groove and through the slots behind (actually, in front of) the pulley. This oil mist, of course, settles out inside the engine compartment and can make a real mess. So -- for the crankcase ventilation system to work properly, it is essential that 1) a vacuum is established in the air cleaner, and 2) the hose between the oil filler and the air cleaner be in place so that crankcase gases are sucked up into the air cleaner and thence into the carburetor and intake manifold for burning.

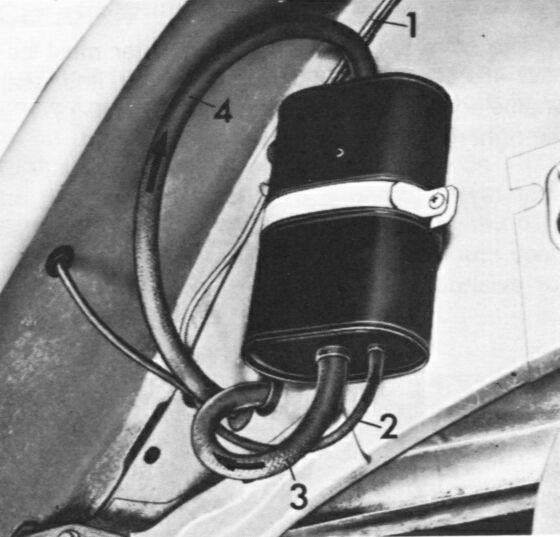

Evaporative Emissions ControlOn later models there is a rubber hose from a charcaol canister in the right wheel well, to the air cleaner. This hose provides suction on the evaporative emissions control system so that gases are directed to the carburetor for burning rather than escaping into the atmosphere. Evaporated fuel, expelled from a full tank by expansion, is collected in the expansion chamber under the cowl panel in the luggage compartment. From there it escapes into a ventilation line that carries it to an activated charcoal canister located in the right rear wheel well. The activated charcoal absorbs the vapor, preventing it from entering the atmosphere. When the engine is started, air from the engine's cooling fan, through a hose on the upper right side of the fan housing, is directed into the canister, blowing trapped fumes from the activated charcoal into the air cleaner. The filtered vapors are drawn through the carburetor and into the cylinders of the engine where they are burned.

Photo courtesy of Bentley. So for the evaporative emission control system to work properly, there is a nozzle on the upper right side of the fan shroud, through which air is blown to the into the activated charcoal canister, and another on the air cleaner into which air is returned to the carburetor. On the 1973 and later air cleaners, there are two nozzles on the right end of the aircleaner. The furthest one forward has a baffle behind it inside the air cleaner; it is to this nozzle that the hose from the oil filler is directed to draw a vacuum on the crankcase. The other nozzle, furthest to the rear, is the one to which the hose from the activated charcoal canister is attached. The Bentley Manual says "the activated charcoal filtering canister must be replaced after each 48,000 miles or two years, whichever comes first." The canister replacement procedure is easy -

A note of caution: If you have disabled the evaporative emission control system (as many people have), the outlet nozzle on the fan housing and the inlet nozzle on the air cleaner must be plugged. Otherwise valuable cooling air is lost, and the vacuum inside the air cleaner cannot be maintained.

Intake Air Pre-HeatingAt some point, VW added an intake preheating system for faster cold-weather warm-up. The system initially consisted of a pull wire running from the thermostat to a movable flap inside the air cleaner intake. In 1973 and later models, this temperature-controlling flap is controlled by a vacuum system. The intake air pre-heating system added yet another hose, at 2" the largest of the several hoses to the air cleaner. This hose, which is the same size as the fresh air hoses to the fan shroud, collects warm air from the #2 cylinder by way of an L-shaped tube underneath the engine tin. This warm air is then routed up to the air cleaner.

“Pull Wire” Pre-Heat ControlThe carburetor pre-heat system on older model cars works like this: The cooling control flaps inside the fan shroud are linked by a flat rod in the front (front is front of car) and outside of the fan shroud. The cooling flaps are worked by the brass bellows thermostat which is mounted under and between the right cylinders, inside the ducting for the used cooling air. The thermostat has a vertical rod extending from the top, running up between the two cylinders. This rod connects to the cooling flap linkage, and also works the air intake pre-heat system by way of a pull wire (a black ‘sheathed’ single strand of piano wire) which starts on the back (back of car) of the fan shroud just under the generator/ alternator, and loops to the left and up behind the carburetor to the flap in the rectangular air cleaner intake pipe. Under this intake pipe is the 2" paper tube which pulls in warm air from the #2 cylinder by way of an “L-shaped” tube that protrudes up through the tinware. There is an air-preheating regulator valve inside the air cleaner intake which normally closes off the pre-heater inlet. A lever on the side of the inlet connects the pull wire with the cooling flaps inside the fan shroud, and thus to the thermostat pushrod. If the pull wire is missing, you'll be sucking cold air into the carburetor all the time, instead of after the engine has warmed up. When removing the air cleaner you can leave the pull wire attached and just rest the air cleaner at the back of the engine pulley (the cable is just long enough), or you can disconnect the wire to remove the cleaner completely. The regulating flap in the air cleaner is adjusted by sliding the sheath back or forwards through the clamp, so that the flap is open to the warm air pipe when the engine is cold.

Someone wrote - I have been reading your site looking for knowledge on my 1967 Beetle. I have the original oil bath air cleaner with a neck on each side of it with a flap on each side. I noticed the other day that they are clipped up to stay open. There is a weight that hangs down on the outside of the neck that seems to hold it closed. I was playing around with the engine idle and noticed that when I rev up the engine the weight moves. I live in southern California in the city. Should these flaps be clipped open all the time or should they be allowed to move with the engine revs? Also what do they do? Rob responded - The flap on the left side should be loose but weighted so it's normally closed, but will open when the engine is running hard and pulling in a lot of air. The flap on the right side of the car should have a pull-wire (like a mower throttle cable) running to a crank on the flap unit inside the fan shroud on the right side of the engine (I bet it's not there!). With this system, when the engine is cold both air inlet flaps are shut and the carburetor air is pulled up from the right side cylinder head area through the paper tube, so it gets warm air as soon as the engine starts to heat up. As the engine gets fully warmed, the thermostat opens the cooling flaps inside the fan shroud to increase the cooling airflow, and this action also opens the right side air inlet flap so now the engine is running on cool inlet air (the underside of the carburetor is now being heated by the heat riser under the manifold which uses hot exhaust gas). Now the engine is running on the right side air inlet until you floor the throttle and then the weighted flap on the left side opens too. That's used on the 67 and 68 years only. For 69-71 they dropped the left side air inlet and increased the size of the right side inlet, so it became all-or-nothing for warm/cold air through the single inlet with the pull-wire flap mechanism (and from about 72 on they used a vacuum/temp switch device). If the pull wire is missing, and the cooling flaps inside the shroud will probably be missing too (should get them replaced as soon as you can - they are quite important for fast and EVEN warmups), then the flap in the air inlet should be fixed open. It will mean the engine is a little rough when cold, but the engine only needs warm air for the initial warmup period, then it should be running on cold air, with the heat riser under the manifold providing the necessary heat to stop icing etc.

Vacuum-Controlled Pre-Heat SystemsIn 1972 VW changed to a vacuum-controlled intake pre-heating system for faster cold weather warm-up. A small vacuum line from a port in the intake manifold directly below the carburetor supplies vacuum via the tube, to the temperature sensor in the top of the oil bath cleaner (and from 73, to the bottom of the paper air cleaner). From there vacuum is carried by another small tube to the operating mechanism for the warm air intake, mounted on the air intake tube. With the inlet air cold and the engine running, the air cleaner sensor feeds vacuum to the mechansim in the air inlet, which opens the regulating valve allowing warm air from the cylinder heads, by way of the paper intake, into the air cleaner and carburetor. As the air inside the air cleaner warms up, the sensor shuts down the vacuum and the air inlet gradually switches to the cold air inlet as the vacuum bleeds out of the inlet flap mechanism. For either the pull wire or vacuum system, There is/was a paper tube down to the breastplate, and a metal L shaped tube under the breastplate to pick up warm air off the right side finning. If the paper tube is missing and the breastplate hole is open,the L shaped tube underneath is probably missing too. This means that the pre-heat system has been disabled (which many people do). We do not recommend this! But -- if the system is disabled in your car, you must plug the large hole in the tinware breastpale where the warm air tube connected to the L-shaped warm air adapter pipe. Otherwise you will have hot, used cooling air sucked into the engine compartment and into the cooling fan, contribution to overheating and smelly air in the cabin. It is very common practice to remove the thermostat. Again, we do not recommend this. If the thermostat is removed, the condition will be the same as if the pre-heater tube were missing -- the engine would be very slow to warm up and the engine may run rough.

Aftermarket Air CleanersA frequently-asked question - I'm thinking about changing out the big hurky air cleaner on my Bug for a smaller chrome one. Any advice? Advice regarding aftermarket air cleaners generally runs against them, in favor of the stock VW air cleaners. Although the chrome filters look nice on a tricked-out engine, our advice is to retain the oil-bath or paper-filter air cleaner since it's more reliable and provides several functions which the aftermarket filters do not. Here are some specifics:

|