|

||

|

|

Accelerator Cable Replacementexperience on August 12/13, 2004, and again after a cable upgrade in November 2007. Note: The accelerator cable connects the carburetor (throttle lever) with the accelerator pedal. The routing of the cable from the accelerator pedal rearward is as follows -

Note: The flexible guide tube containing the accelerator cable runs over the top of the transaxle, inboard of the clutch cable. Working with the flexible guide tube and fitting its flared end over the metal tube projecting forward through the firewall is VERY awkward. The left rear wheel must be removed, and light is essential - and only one arm at a time can be reached into that area. It feels SO good when you finally get it! :-)

Removing the Accelerator CableThe following procedure for removal replacement of the accelerator cable was adapted from procedures you will find in the various manuals, augmented by our own experience.

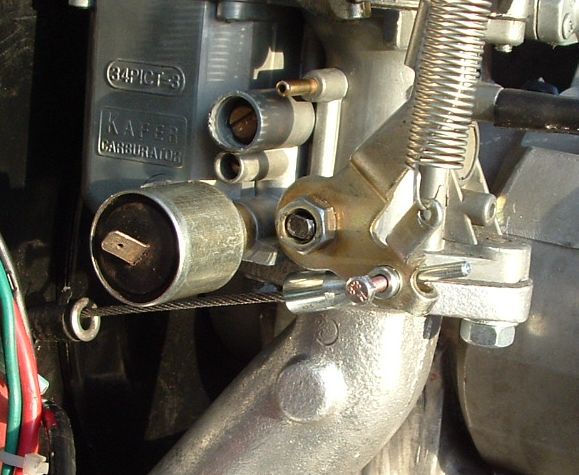

Barrel ClampNote: The barrel clamp must be prevented from turning while you loosen the it in. We've had best success with a small vice grip pinching the cable against the bottom of the throttle lever so it can't move while the bolt in the barrel clamp is tightened or loosened.

Note: This job is very awkward at best -- it is virtually impossible if the left rear wheel is not removed. Accelerator Cable InstallationFirst of all, make absolutely sure that your cable is the proper length. Thanks to Aircooled.Net for the following information -

Note: If you have removed the flexible guide tube for any reason, at this point you will have to push the cable rearward through the rubber boot and flexible guide tube, then slip the rubber boot and forward end of the guide tube into place. Make sure the cable protrudes from the rear end of the guide tube.

Note: It is difficult to see the end of the tube protruding though the firewall -- there's so much stuff in the way (and if you wear bifocals like I do!). It will be above and inboard of the clutch cable. Also, the rubber over the top of the transaxle (especially if it is new) may be in the way and prevent the tube from protruding through. If this is the case, you will have to cut a notch in the rubber with a sharp knife to allow the tube through (easier said than done!).

Note: This is quite difficult, considering that the tube through the fan housing is free to move forward-to-back. If you don't have an assistant to hold this tube in place, fashion a piece of wood to place between it and something else in the engine compartment to keep the tube from moving rearward while you install the flared fitting on the end of the flexible guide tube over the fan housing tube. We placed a little block of wood between the end of the tube, against the fan housing wall, pinned against the vacuum nozzle on the intake manifold.

Note: If you hook up the S-shaped fitting the other

way (i.e., inserted through the hole from the side opposite

the brake pedal), it will come apart the first time you put

your foot to the accelerator pedal.

Note:There is a significantly improved cable ("bulletproof") available from Aircooled.Net. This cable incorporates a flat-paddle design for attachment to the accelerator pedal (see the picture below). The paddle simply bolts to the pedal connection(loosely), with nylon washers and a Nyloc nut - tight without being tight).

BugPack Cable ConnectionNote: The only drawback we see to the stouter "bulletproof" cable is its lack of a solid metal end connector as on the stock cable. Without this, the barrel clamp screws down directly onto the cable, creating a tendency for it to become mangled over time, especially if the carburetor is repeatedly removed. This problem can be overcome through the use of a throttle cable extension kit available from Bugpack. CAUTION: Make absolutely sure that the barrel clamp rotates freely in its two holes at the base of the throttle lever. If it doesn't, it will hang up and cause the accelerator lever to stick, usually at a high rpm. You may be tempted to tap it into place with a hammer, but don't do it! If it's that tight, it won't rotate as the accelerator cable is pulled back and forth, and it will stick. Take the barrel clamp out and polish it with emery cloth until it rotates freely in the holes as the base of the throttle lever.

Note:The throttle arm should move almost 90 degrees from closed to fully open - when closed it sits almost (not quite) horizontal across the carburetor throat and when fully open it stands vertically in the throat. So if you're getting more movement by pulling on the throttle arm (than the accelerator pedal provides) then the cable is not properly adjusted. Note: The Bugpack cable is very long and must be cut to length. Making sure the choke is open, cut the cable, leaving about one-ince extra after the barrel clamp. It is recommended that the cable end be soldered to prevent the cable from unraveling. Dave uses a throttle cable extender, which attaches to the cable and then goes through the barrel clamp. The screw in the barrel clamp tightens down on the cable extender instead of the cable. Great look, too!

Throttle Cable ExtenderNote: Rob just pulls the accelerator cable back finger tight (NOT with any kind of tool) and then secures it in place with the barrel clamp, and it works just fine. Here are some details on how that's done -

Properly Connected Accelerated Cable

|

||||||

|